Did you have a brilliant concept for a product but were left to wonder whether it was going to be a success? Have you ever had to convey your ideas and product's design to colleagues as well as investors or customers from outside? Rapid prototyping is changing the plastic part manufacturing process, making it possible for designers and engineers to design quality prototypes that appear like, feel, and function just as the final product.

When designing the process begins with an idea or concept and then it is a hand-drawn or digitally designed that is then test-driven using prototyping. Rapid prototyping solutions is the method of rapid creation of a prototype in order to showcase and demonstrate the design of a product. Rapid prototyping is based on three-dimensional computer-aided design information (CAD) to design and layout, and generally utilizes 3D printers to produce. Because prototypes aren't made from the same materials that the finished product the long-term durability of the design can't be assessed.

A clear visual representation of design concepts By using rapid prototyping, engineers and designers are able to clearly communicate their concepts for design with colleagues and investors as well as customers. It's now easier for them to present their ideas clearly and to visually determine whether there are any modifications that are required in the design.

Increased Efficiency Prior to the time that the invention of rapid prototyping the designers and engineers were forced to wait for an extended time to build prototypes and, if a new prototype had to be designed and cost a lot of money to create. By using rapid prototyping, businesses are able to save time, money, and time by using the same equipment to design and build different prototype ideas.

Design that can be customized lets engineers and designers modify models and concepts quickly to satisfy the needs of the customer. Small components that were difficult to incorporate are now easily produced in a prototyping design concept.

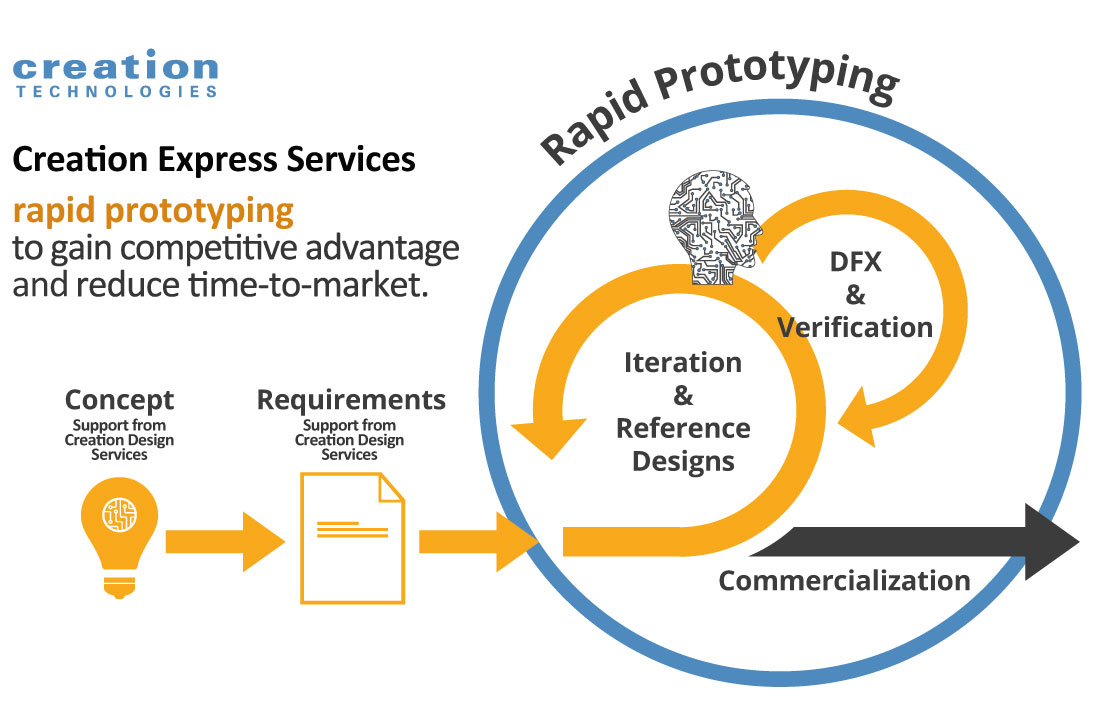

Increase speed of Time to Market With rapid prototyping, businesses can accelerate their time to market by utilizing improved technology as well as speedy and simple revisions to the design Based on testing with physical objects and feedback.

Concept Prototypes If your goal is to come up with a variety of ideas in a short time, concept prototyping is the solution. This method lets engineers and designers present their designs and evaluate the product's capabilities. Because of the speedy turnaround time and the necessity to try out more ideas, 3D printers are the most efficient method to create conceptual models.

Functional Prototypes Functional prototyping allows engineers and designers to illustrate how an item will perform under pressure as well as in the real world. Functional prototyping is a great way to evaluate the style, fit functionality, and function of the product prior to proceeding to manufacturing. Based on the final purpose, a prototype could be printed 3D using a variety of engineering plastics to evaluate the effectiveness in a specific setting.

By using rapid prototyping, engineers and designers constantly improving their products and are able to effectively address problems that arise in the prototyping process. These new techniques are helping manufacturers create innovative products at a lower cost.